Innovative Solutions in Petfood Engineering and Technology

Welcome to our Petfood Engineering & Technology platform, where we transform complex challenges into innovative solutions. Explore advancements and expertise that redefine the boundaries of possibility within the petfood industry.

M Petfood Services

DESIGN OF DRY & WET PETFOOD FACTORIES AND EQUIPMENT

DESIGN OF LIQUID PALATABILITY ENHANCER PROCESS LINE AND EQUIPMENT

ALL RECIPES FOR PETFOOD

DIE PLATES AND KNIVES FOR EXTRUDER

About M Petfood

With over 30 years of hands-on experience in the petfood industry, M Petfood is a trusted global partner for companies seeking expertise, innovation, and practical support in every aspect of petfood production. From designing complete processing lines to optimizing existing operations, we deliver solutions that strengthen efficiency, quality, and profitability.

Who We Are

M Petfood is a team of industry professionals with decades of experience working directly in wet and dry petfood production. Our expertise covers engineering, formulation, process optimization, equipment design, and product development — allowing us to support petfood manufacturers at every stage of their growth.

Our Mission

Our mission is to provide reliable, science-based, and cost-effective solutions for the petfood industry. We help manufacturers produce safe, nutritious, and competitive products while improving operational performance and reducing production costs.

Our Vision

We aim to be the leading technical partner in the global petfood industry, recognized for practical knowledge, innovative thinking, and long-term support that drives sustainable success for our clients.

What We Do

Designing New Processing Lines

We create complete wet and dry petfood processing lines, tailored to each factory’s capacity, budget, and production goals.

Our services include:

Full engineering design

Layout planning and workflow optimization

Equipment selection

Commissioning support

Training for production teams

Recipe Development & Formulation

M Petfood develops recipes that balance nutrition, cost, performance, and palatability.

We support:

Dry, wet, and semi-moist petfood

Treats and snacks

Special and functional diets

Ingredient selection and sourcing

Nutritional optimization

High-Quality Die Plates & Knives for Extruders

We manufacture and supply premium die plates and extruder knives designed for:

Better shaping and consistency

Longer lifetime

Lower energy consumption

Improved product appearance

Reduced downtime and maintenance

Cost Optimization & Cost Control

We help factories reduce costs without reducing quality by:

Ingredient cost optimization

Energy and efficiency improvements

Waste reduction strategies

Production flow optimization

Cost killing and continuous cost control systems

Business Optimization

For long-term growth, M Petfood supports:

Factory audits

Process efficiency improvements

Organizational workflow planning

Productivity upgrades

Line Modernisation

We modernize old production lines with:

New technologies

Updated process controls

Better energy efficiency

Improved safety and hygiene standards

Higher output with the same or lower cost

Problem Solving

We provide fast and effective solutions for:

Production issues

Mechanical or process failures

Texture, shape, moisture, or palatability problems

Batch inconsistencies

Product rejects or quality concerns

R&D and New Product Development

Innovation is a key part of what we do.

We support:

Development of new product lines

Testing and pilot production

Ingredient trials

Texture and process innovation

Prototype evaluation

Feasibility Studies

Before investing, we help clients make informed decisions by providing:

Market and product feasibility

Cost and profitability analysis

Technical and production feasibility

Risk evaluation

CAPEX and ROI predictions

Why Choose M Petfood

30+ years of practical industry experience

Complete support from idea to production

Technical, engineering, and nutritional expertise

Proven problem-solving capabilities

Strong focus on cost control and efficiency

High-quality tools, components, and solutions

Long-term partnership approach

DESIGN OF DRY & WET PETFOOD FACTORIES AND EQUIPMENT

Comprehensive Support for Wet & Dry Petfood Projects

Integrated Production Line Development

We prepare complete technical documentation for both wet and dry petfood lines. This includes:

full process flow charts covering all planned recipes and formats

identification of potential equipment suppliers

preparation of inquiries and technical specifications

detailed analysis and comparison of supplier offers

organisation of tender procedures and negotiations

development of final factory layouts (wet and/or dry)

supervision of equipment installation on-site

first industrial production runs based on our developed recipes

Product Category Management & Market Strategy

We support clients in effectively positioning their new products by offering:

development of a market entry strategy

category segmentation and identification of product niches

defining physical product characteristics (form, shape, density, size)

determination of packaging formats

preparation of legal declarations according to EU requirements

creation of marketing claims for packaging

compilation of final product lists with complete specifications and chemical parameters

Recipe Development & Raw Material Management

Our formulation and ingredient services include:

full recipe development for all product categories (private label, economy, premium, super-premium, functional diets)

mineral and vitamin premix formulation

recipe cost optimization before production launch

preparation of raw material specifications

identification of qualified raw material suppliers

supplier audits when needed to ensure required quality standards

Factory Start-Up & Finished Product Management

During commissioning, we take responsibility for:

performing the first industrial production trials for each recipe

implementing corrective actions based on results

preparing final specification sheets and product data sheets

defining the final physicochemical parameters of finished products

Quality System Development

To ensure stable production and compliance with standards, we offer:

theoretical training for technologists and operators

practical training during the start-up phase

preparation of foundational quality system documentation

creation of laboratory analysis lists and recommended testing methodologies

Additional Strategic Services for Investors

We assist investors from the earliest concept stage, helping them design a factory that is efficient, cost-effective, and scalable:

support in selecting the optimal factory location

consulting with architects on building layout, production flow, and functional areas

defining factory capacities for both wet and dry systems and establishing the production mix

conducting preliminary market analysis (categories, volumes, customer types)

identifying necessary technologies and preparing equipment lists with budget estimates

aligning production capacity with the total investment budget

calculating utilities and energy requirements (water, gas, electricity)

organising reference visits to comparable petfood factories

preparing staff requirement estimates

defining product mix, raw material usage, and category segmentation

preparing cost and sales projections, production plans, and schedules

identifying automation and robotisation options to reduce costs and increase efficiency

analysing applicable legal and regulatory requirements in the petfood sector

preparing process descriptions and production flow documentation for each product category

DESIGN OF LIQUID PALATABILITY ENHANCER PROCESS LINE AND EQUIPMENT

Palatability Enhancer Production

Palatability enhancers are one of the key functional ingredients in every dry petfood formula for both dogs and cats. When chosen correctly, they significantly increase palatability and strengthen product acceptance across all market levels — from economy and private label ranges to premium and super-premium lines. In such a competitive category, the right palatability enhancer can noticeably improve eating performance and elevate your product above competing brands. The market offers many reputable producers capable of supplying materials suitable for every segment of the dry petfood industry.

However, palatability enhancers also represent one of the most expensive components in a dry petfood recipe. In many formulas, their cost accounts for a substantial percentage of the total recipe price. Depending on the positioning of the product, this can strongly affect overall production costs and restrict competitive pricing.

M Petfood provides a practical and profitable alternative.

We support manufacturers in developing and installing their own lines for liquid palatability enhancer production. Our solutions cover all capacity levels and include a full technological package: complete process-line design, production know-how, and ready-to-use manufacturing recipes. Once the system is running, you can produce your own palatability enhancers, control their quality internally, and significantly reduce the cost of your final recipes.

By lowering dependency on external suppliers, the cost of palatability enhancers — and therefore the cost of finished dry petfood — drops immediately. This allows the investment to pay for itself in a short time. An additional benefit is the R&D capability you gain. With in-house production, you can test new raw materials, develop improved flavour solutions and continuously enhance the palatability of your products. This gives you a competitive edge, not only through savings but also through innovation.

Palatability enhancers (digests) are one of the most influential components in dry petfood recipes. They directly impact flavour acceptance and eating performance in dogs and cats. The right enhancer improves product competitiveness across all market segments.

Importance of Palatability Enhancers

Essential for all dry petfood formulas — economy, private label, premium, and super premium.

Improve flavour, aroma, and overall pet acceptance.

Strengthen product quality perception in a competitive market.

Available from many established global suppliers covering every segment of the industry.

Cost Challenges in Standard Production

Palatability enhancers are among the most expensive raw materials in a dry petfood recipe.

A significant portion of the final recipe cost comes directly from these materials.

High reliance on external suppliers increases vulnerability to price fluctuations.

Recipe optimisation becomes limited when enhancer costs are high.

Our Solution: In-House Production Lines

M Petfood provides complete support for building and operating your own liquid palatability enhancer production line.

Our service includes:

Process & Line Design

Designing a complete process line for liquid palatability enhancer production.

Capacity options for small, medium, and large factories.

Full technology transfer and production methodology.

Equipment Consulting

Identifying required equipment for the chosen production capacity.

Preparing supplier inquiries and analysing technical offers.

Support in negotiations and purchasing processes.

Production Recipes & Technology

Providing complete sets of production recipes.

Delivering detailed processing parameters and technological guidelines.

Advising on raw material selection and supplier choice.

Installation & Factory Start-Up

Supervising assembly and installation of equipment.

Running first production batches together with your team.

Conducting necessary adjustments based on test results.

Training & Documentation

Training for operators and technologists.

Preparing basic quality documentation required for stable production.

Establishing laboratory procedures for product control.

Key Benefits for the Investor

Immediate reduction of recipe costs thanks to cheaper internal production.

Short investment payback time due to significant savings on purchased enhancers.

Full quality control over your palatability enhancer materials.

Independence from external suppliers and protection against market price changes.

New R&D possibilities, allowing experiments with raw materials and flavour systems.

Improved competitiveness through better palatability and lower production costs.

Strategic Advantage for Your Company

Producing your own palatability enhancers transforms them from a major cost into a strategic asset.

You achieve:

Lower production costs

Higher product palatability

Faster recipe optimisation

Stronger market position

Long-term technological advantage

ALL RECIPES FOR PETFOOD

Recipe Development for Petfood

A recipe is the foundation of every new product and every optimisation project. Proper formulation requires balancing nutritional needs, product functionality, legal requirements, raw-material quality, sensory expectations, and production efficiency. At M Petfood, we combine all of these elements into precise, cost-effective and market-ready solutions.

Recipe Development Principles

When preparing recipes for petfood, we take into account:

Nutritional requirements for dogs and cats

Product functionality and targeted performance

Legal norms and feed-regulation compliance

Approved raw materials and feed additives

Quality, price and availability of raw materials

Visual and sensory characteristics of the final product

Technological impact of the recipe on production lines

Overall cost efficiency and competitive positioning

Our approach guarantees formulas that are safe, nutritionally balanced and optimised for both production and market demands.

Classic Formulas

Our classic formulations are designed to deliver high-quality, well-balanced petfood at competitive cost levels.

We ensure:

Recipes aligned with nutritional guidelines for different life stages

High palatability and digestibility

Compliance with all EU feed regulations

Raw-material optimisation for cost control

Sensory appeal that meets consumer expectations

Stable technological performance on production lines

These recipes are ideal for economy, private label, premium and super-premium ranges.

Custom Diets

The growing humanisation of pets increases the demand for specialised, tailor-made diets. Custom products require careful planning to ensure safety, compliance and functional performance.

Our support with custom diets includes:

Designing recipes for specific customer or brand requirements

Incorporating new functional ingredients and additives

Creating formulas with targeted health or nutritional benefits

Full verification of legal requirements and labelling rules

Ensuring feed safety, stability and long-term product quality

Cost optimisation at each development stage

Defining necessary research and analytical tests for validation

You receive a complete documentation package ready for industrial production, ensuring high customer satisfaction and strong pet acceptance.

Veterinary Diets

Lifestyle changes, environmental factors and dietary habits contribute to the rise of health issues in pets. Nutritional support plays a key role in preventive care and management of chronic conditions.

We develop specialised veterinary formulas that support:

Gastrointestinal sensitivity

Hepatic and renal function

Weight control and obesity prevention

Skin and coat problems

Oral health issues

Allergies and food intolerances

Joint and mobility concerns

Other lifestyle-related conditions

Our veterinary diets combine:

Clinical nutritional principles

Functional ingredients with proven effects

Safe and compliant ingredient selection

Optimised cost structure

Clear documentation for regulatory approval

These dedicated recipes help manufacturers deliver targeted solutions that support the well-being of pets with specific health challenges.

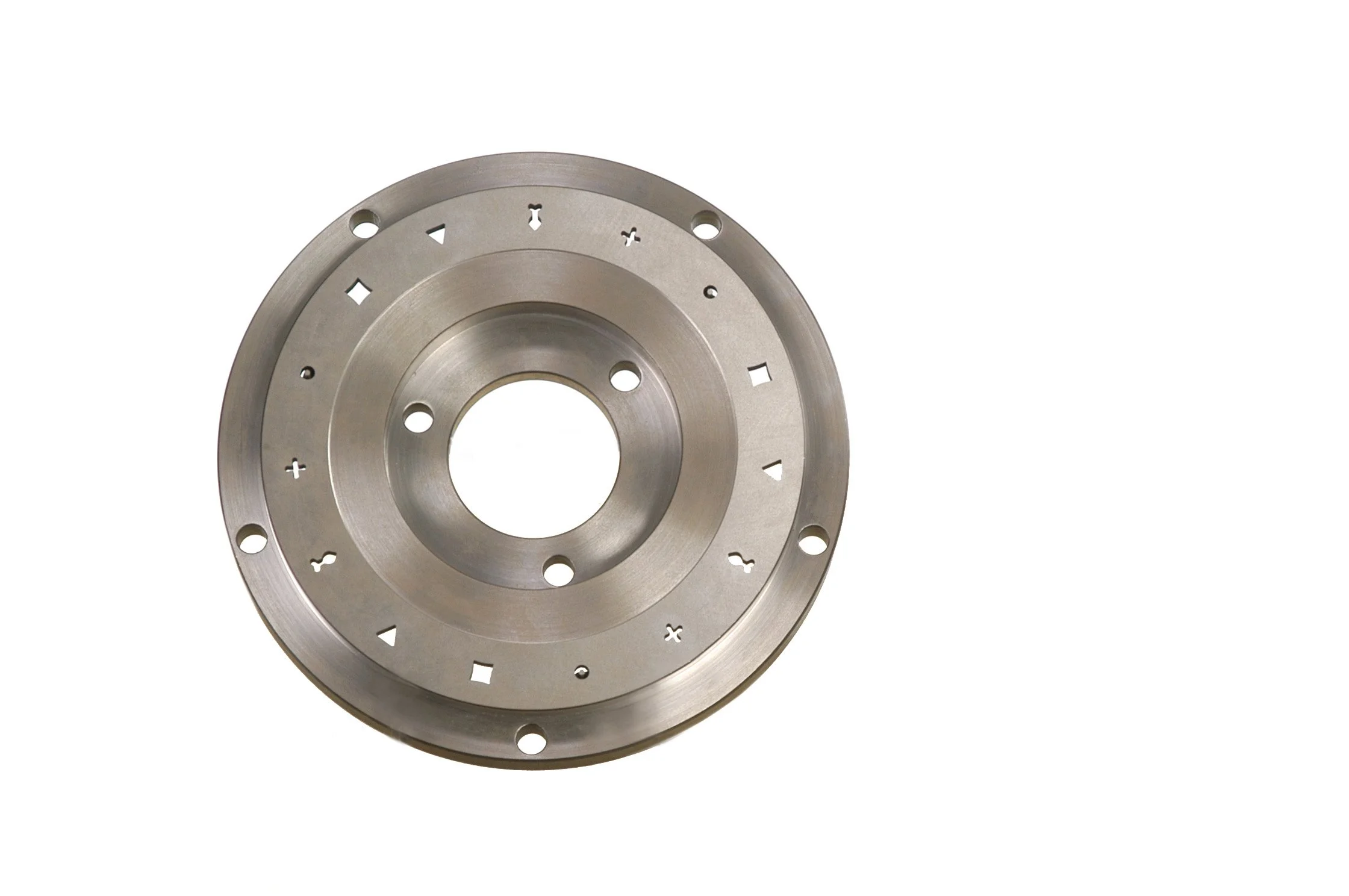

DIE PLATES AND KNIVES FOR EXTRUDER

Die Plates and Knives for Extruders

High-quality die plates and knives are essential components of every dry petfood extrusion line. Their design, durability and precision directly influence product quality, process stability and production efficiency. At M Petfood, we offer complete support in selecting, designing and manufacturing die plates and cutting systems tailored to your equipment, product range and capacity.

Importance of High-Quality Die Plates and Knives

Die plates and knives determine the final characteristics of extruded petfood, including:

Shape, size and texture of kibble

Density and mechanical durability

Uniformity and visual appearance

Cutting precision and product consistency

Extruder load, energy efficiency and throughput

Impact on wear, maintenance cycles and production downtime

Correct design and material selection significantly reduces operating costs and improves product quality.

Die Plate Design and Production

We provide comprehensive solutions for die plate development, ensuring high performance in daily production.

Our support includes:

Custom Design

Designing die plates for all extruder types and capacities

Tailoring hole geometry, thickness and distribution to target recipes

Developing shapes for standard, premium and functional petfood products

Material Selection

Choosing optimal steel grades for durability and corrosion resistance

Options for hardened, wear-resistant and long-life materials

Precision Manufacturing

CNC machining for high dimensional accuracy

Controlled surface finishing to reduce friction and improve flow

Testing and adjustment before delivery

Optimisation for Cost & Performance

Reduced die pressure to lower energy consumption

Improved flow dynamics for stable throughput

Extended lifespan to reduce replacement frequency

Knife Systems for Extruders

High-performing knife assemblies ensure clean cutting and uniform kibble size.

We provide:

Knife Blades

Long-lasting blades manufactured from high-strength alloys

Options for standard, serrated or custom cutting profiles

Knife Hubs & Holders

Balanced construction for smooth, stable rotation

Designs compatible with major extruder brands

Cutting System Optimisation

Ensuring compatibility between die plate and knife set

Adjusting blade angles for perfect cutting quality

Reducing fines, waste and dust formation

Maintenance Planning

Guidelines for sharpening, replacement and performance monitoring

Wear analysis and recommended replacement intervals

Technical Support & Engineering Services

M Petfood offers end-to-end assistance for die plates and knife systems.

Evaluation of existing die plates and knives

Performance analysis on your current extrusion line

Custom modifications to improve product quality

Troubleshooting of cutting or extrusion problems

Technical documentation and safe-use guidelines

Fast production of spare die plates and knife sets

Benefits for Your Factory

Choosing M Petfood die plates and knives provides:

Improved kibble quality and visual consistency

Longer equipment life and lower maintenance costs

Higher production stability and energy efficiency

Reduced downtime from tool replacements

Precise product shaping for every market category

Better cost control thanks to extended durability